Ancient and Medieval States

Background

Metal Mining and Sources

Earliest Mining

Mining and the extraction of metal for jewellery, weapons and household utensils started long before money plagued the thoughts of men. Gold mining goes back at least to the 5th millennium BC {1} and gold ornaments were being exchanged or traded throughout the Chalcolithic period (4th-3rd millennium BC) in Europe and Asia. {3} Silver was mined as early as 3000 BC in Anatolia, and probably not much later in several Mediterranean islands. {3} Copper production appears, probably independently, in many places: Turkey (7,000 BC), south Siberia (3,500 BC), Africa (3,000 BC), western China (2,700 BC), Europe (2,100 BC) {2-11} Copper was soon mixed with the much rarer tin (from Cornwall, Brittany, Turkey, Iberia, Malaysia, Yunnan or Afghanistan) to make the harder bronze needed for weapons and farming tools. {12-14} All this speaks of enterprising communities linked by well-travelled trade routes, and indeed the salvage from a 14th century BC vessel that sank at Uluburun off the southwest coast of Turkey included a wide variety of goods from the eastern Mediterranean: 10 tons of copper ingots from Cyprus, 1 ton of tin ingots, heaps of blue-and-turquoise-coloured glass, great ebony logs, elephant tusks, pottery, cylinder seals, and gold scrap from Egyptian jewellery. {15}

While ore deposits are not absent from most countries, they are often small, scattered and soon exhausted. The most accessible were secondary deposits, gold placers in particular, which could be worked cheaply by hydraulicking and the metal concentrated by simple washing techniques. {16} Deposits that yielded millions of tons of contained metal, however, and went on year after year making their owner's fortune, belonged to a few rare types. Those unusual coincidences of geological settings are nowadays the object of sustained study and exploration programs too expensive for any but major mining companies to contemplate. Finds in the past were more by chance, and miners, skilled though they were, and by nature optimistic, rarely grasped the full dimensions of their finds. There were no drilling machines to sample the rock hundreds of metres ahead of present workings, nor the blasting and earth-moving equipment to excavate great open pits and benefit from computerized economies of scale. Miners and mine owners often lived from month to month. All phases were primitive: mining, smelting and refining. Where the ore was plentiful, as iron deposits generally are, the smelting technology could be difficult, but the techniques were sufficient mastered to usher in a widespread iron age in Africa, Asia and Europe. The Hittites were smelting iron by the second millennium BC {17} and the Chinese, who used iron occasionally for coinage, by the 5th century BC. {18} The Romans, who typically put matters on an industrial scale not seen again till our own 19th century, were achieving 1.5 kg of iron per head of population per annum from deposits scattered across the empire, but particularly from Spain and Noricum (Austria). {19}

The capital to develop large mines was not easily raised by small states, however, and the labour had usually to be supplied by convicts and/or slaves captured in war or colonial expansion. When those sources dried up, as they did in the second half of the Roman empire, and European in the Middle Ages, freemen came to fill the gap, and those freemen in Europe organized themselves into stout communities that developed tunnelling and dewatering skills, in time forming guilds that took trade secrets with them when they moved to new mining areas. Nonetheless, most operations required hard manual labour. The unfortunates were commonly worked to death. Even the classical authors, inured far more than we are to the savageries of war and slavery, felt some pity for these subterranean wretches, and conditions in the mines of Peru and Mexico excited general horror. Millions of native people died of injury, disease and unremitting cruelty. {20}

As in Europe, it was not generally the mine owners who made fortunes, however, but the businesses supplying rations, textiles, tools and mercury (to extract the silver) — goods that were advanced against future gold and silver deliveries. Beyond those local merchants stretched a vast chain of businesses that linked mine to town to capital city to port and finally to Seville or Cadiz. {43}

Greece

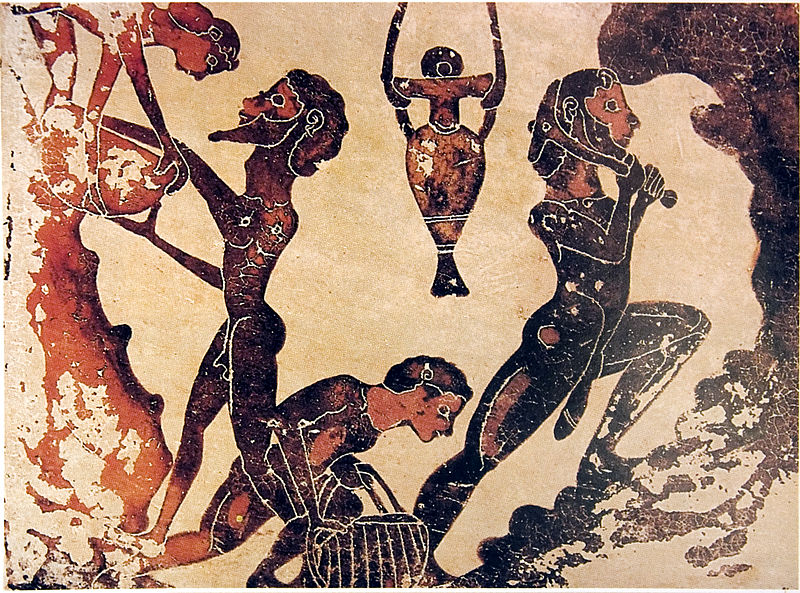

The lead and silver veins at Laurion, some 50 km southeast of Athens, may have been worked from the 10th century BC, but it was a major find around 483 BC that allowed Athens to greatly expand her navy and defeat the Persians at Salamis in 480 BC, so laying the foundations for Athenian and Greek power in the region. The ore was galena (lead sulphide) containing some 30-300 ounces of silver to the ton. Over 2,000 shafts were sunk in these mines, which accessed small galleries, often no more than two feet across. The mine was owned by the state, which leased out production to private contractors paying a fixed sum plus a percentage on the production. The work was exceptionally hard, and slave labour had to be employed throughout: an early 'capitalist' affair which needed luck and careful management to yield a profit. Though as many as 30,000 were employed in the height of mining in the 5th century, production gradually declined towards the end of century as the richer veins became exhausted and the area was sequestered under Spartan occupation, though they revived again under the Romans. Extraction was followed by manual sorting of the ore and then washing, tanks being constructed to collect rainwater for the purpose. {21-25} {39}

China

China needed large quantities of copper, lead and tin to manufacture her cash coins, which were cast in huge quantities. Up to 5 million strings per year were turned out by the Northern Song dynasty, where each string held a nominal 1000 coins. {26} Until the late seventeenth century AD, when Japanese supplies became important, the main sources were many small local mines. In early times the distant Urals may also have been a source: it is noticeable that the ages of the first bronzes cast by pre-Qin China become progressively younger eastwards. {27-31}

Rome

Rome mined metals throughout the empire but the large and rich sources were in Noricum (Austria), Dacia, Britain and the RioTinto area of Spain, (the last being geologically similar to the later Rammelberg find noted below). All four produced appreciable gold, native in Dacia and Britain but associated with iron ore at Noricum and with base metals in Spain. The ore was dug out with iron and occasionally stone implements, and deeper mines ventilated with special ventilation shafts. Water wheels were used to crush ore and drain mines. Though somewhat crude, Roman metal working included smelting, melting, roasting, casting and cupellation. Most furnaces were heated by wood or charcoal, but coal was used in Britain and the Rhineland from the 2nd century AD. {32-33}

Africa

Gold was mined in western Arabia and occasionally in east Africa from earliest times. {44} The shallow but enormous gold fields of Ghana, Niger and Mali became important later. {34-38}

Central Asia

The Islamic dynasties obtained their gold from the Urals-Altai area, Tibet and India, — supplemented by important supplies from Nubia, north Africa, south-east Asia and (most particularly) west Africa.

Rich silver lodes were mined in four phases in central Asia. {44}

| Phases (AD) | Ilak-'Shâsh' (Karamazar Mts: Uzbekistan) | Mad'in Benghir (N.W. Afghanistan) | Pamir (Kugan-Tugaj: Tadjikstan) | Headwaters of Talas River (Khirghizia) | Total Silver Production (kg) |

| 480-650 | 300 | 7,300 | - | - | 7,600 |

| 730-850 | 23,000 | - | - | - | 23,000 |

| 850-950 | 22,700 | - | 300 | - | 23,000 |

| 950-1140 | - | - | 7,500 | 60 | 7,560 |

Europe

Coinage largely disappeared from Europe after the fall of the Roman Empire, though there were sporadic strikings in silver: diminutive sceats and then pennies, often modelled on Byzantine and Islamic issues. Then, in the late ninth century, came the find of Rammelsberg in the Hartz mountains of Germany, followed, in 1168, by the rich find of Freiberg. A silver fever spread across Europe in the late 12th and early 13th centuries, unearthing new deposits in the Black Forest, Bohemia, Hungary, the eastern Alps and at Iglesias in Sardinia. The Bohemian Kutná Hora discovery of 1298 generated enormous quantities of silver. Some 20 tonnes of silver were extracted every year from 1300 to 1340, generally by seasoned Saxon miners who brought with them their expertise, their customs and traditions of personal liberty. {39-41}

So arose the early 'capitalist' system. Merchants and merchant bankers supplied the capital and handled the marketing of products. The miners supplied labour, in enormous quantities sometimes: the Schwaz and Falkenstein mines of the Tyrol employed over 12,000 men in in 1550, 500-600 alone for pumping out the water. That workforce was also dependent on others for their rations, another much-complained-about source of profit to merchants and mine owners. In time mining became less local, and increasingly Europe obtained its iron from Sweden and Russia, its copper from Norway and Sweden, its tin from Cornwall and Siam, its silver from Japan and America, and its gold from China and America. Behind all those sources, as important as the mines themselves, lay complex networks of merchants to supply goods, market products and provide the necessary finance. {43}

References and Further Reading

Need the 44 references? Please consider the inexpensive ebook.